Submarine consultancy

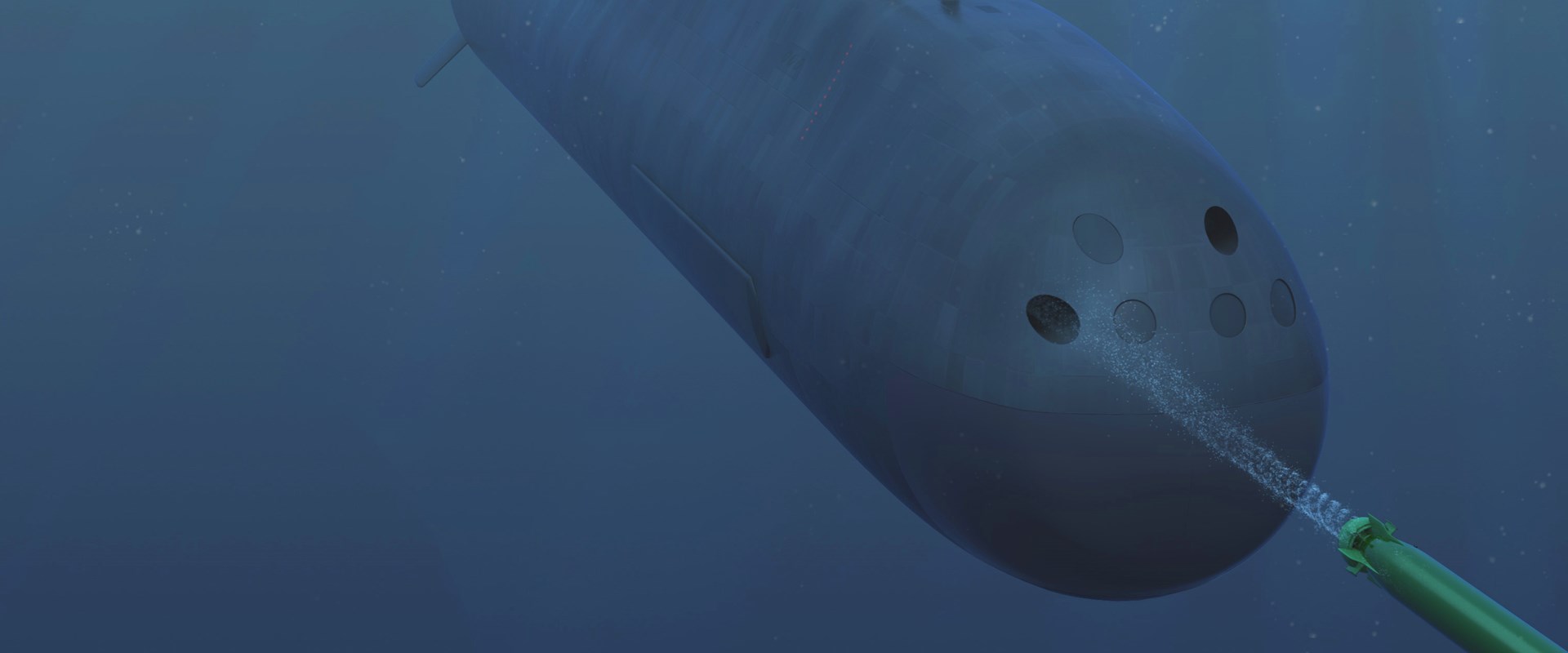

Our knowledge of submarine design, availability and reliability, enables efficient solutions to complex problems.

Key contact

Director, Submarine Program - Canada

Ottawa, Canada

Ken Cox, A C.E.T, CD ContactSubmarines represent the most complex of engineering machines operating in the most challenging environment, in which other underwater systems are also employed. We help you navigate that complexity, bringing a whole enterprise perspective to the many technical and contractual issues involved and building a complete understanding of engineering, quality, safety, availability, costs and risks.

We use our operations experience and technical ability to deliver practical solutions, and we assure the effectiveness of those solutions through our domain, safety, and regulatory knowledge.

We understand the submarine and underwater systems ethos and bring a working style that is collaborative and collegiate, working to promote the common good by improving the interfaces between the many parties required to address complex acquisition programmes.

We remain flexible and agile, flexing to meet different demands across the project lifecycle and responding to the budget and approval delays and emerging issues common on such complex programmes.

In the early phases of the project lifecycle, we have a portfolio of submarine concept designs that we can develop to meet your needs.

In uncertain economic times, submarine concept design becomes an increasingly important phase in meeting the demand for cost-effectiveness in defence procurement, with most programme costs being committed. To make critical decisions early in the programme and ensure that value for money is achieved, requirements and met in the design need to be fully understood. As part of this, possible trades need to be identified to ensure those capability requirements are met. The chosen method is suitable for construction within the constraints of available technology. Resources and costs are available and affordable.

Due to the inherent complexity of modern submarines, the process of selecting a preferred design requires the iterative process and comparison of a decreasing number of multiple design strategies in terms of:

Acting as 'customer friend' as the design evolves, we also bring the skills necessary for technical assurance of the whole boat design.

Hydrodynamics: understanding the evolution of submarine hull form (resistance, powering, manoeuvring, n control); applying empirical formulae and CFD modelling; physical validation of hydrodynamic performance.

Weight and buoyancy: ensuring the design balances throughout the lifecycle through pro-active weight management, using hydrostatics modelling tools that grow alongside the design and challenging and controlling margins allowances.

Safety: we evaluate design against crucial safety functions such as watertight integrity, handling of ordnance, fire-fighting and escape, rescue and abandonment, and are part of the UK delegation that attends the NATO Submarine Escape & Rescue Working Group.

Availability: our concept designs reflect an understanding of the features that contribute most to the achievement of an available submarine.

Design for Support: in-service support activities are often not considered adequately during the design phase, which results in the cost and duration of support activities being driven upwards.

Our design teams have a wide range of experience across the platform's lifecycle and can consider support activities as the design is developed. Thus the design is optimised to enable support activities.

Only when you consider the totality of a complex system like a submarine can you be sure you have identified and defined all potential sources of technical risk, cost increase or time delay.

Our holistic requirements engineering approach sees us explore, analyse, negotiate and define user and system requirements to give you a comprehensive specification of your needs. This broad perspective allows for complex linkages to be maintained between user and system requirements.

We create a structured and auditable evidence base to make clear, concise and timely decisions with confidence that your supplier can meet your requirements within performance, budget and time constraints. Integrated management and modelling tools help avoid wasted time, and a through-life approach helps identify potential risks early.

We develop and refine candidate system architectures at all levels to validate requirements and test assumptions, presenting requirements in a clear architecture that shows interrelationships. We develop robust and comprehensive functional and non-functional specifications based on these candidate architectures, providing evidence to support engineering decisions and undertake technology management and planning to support the realisation of the requirements.

We help you navigate your options to make informed, supportable decisions on what will deliver the best possible value for money in use whilst providing the required performance of your asset.

Which option best balances reliability and cost drivers to improve reliability, reduce downtime and improve availability? Which option will reduce your cost of ownership whilst increasing your assets resilience and safety? Which opportunity will allow you to move from reactive to predictive maintenance, armed with a minimum safe and defensible scheduled maintenance strategy?

We help you answer these questions with confidence, whatever the life stage of your asset. We help you identify design shortfalls correctly, influence design improvements, build a more effective repair process and robust support and supply chain.

‘Feasibility’ should not only assure you that you have identified all cost risks and drivers of cost, but it should also support you in making value for money decisions. Our proactive approach to cost management helps you navigate choices confidently, staying focused on reduced time to market and increased overall profitability.

We apply Target Costing, Activity Based Costing, Cost as An Independent Variable (CAIV) and Value Management Techniques to reduce project cost by focusing specifically on the design and manufacture of the product or service and then considering alternative approaches you could use adopt.

We ensure the model outputs we deliver are realistic and error-free and incorporate sensitivity analysis better to understand the resilience of preferred courses of action.

We are ideally placed to conduct design assurance activities, to support in maintenance of design intent through life and to develop system or equipment design change solutions.

We are able to provide independent engineering design services. Technical assurance of our outputs is central to our methodology, supports decision making and reduces the risk of re-work and delays. Maintaining design intent through life is a challenge and the importance is often lost in the pressures of delivering during the in-service phase, which can have serious safety implications as well as driving in-efficiencies in delivery of in-service availability, driving up in-service support costs.

We have a full range of capabilities for provision of post-design services, ranging from development of in-service support solutions to provision of those services, including provision of design changes, authoring of technical documentation and provision of configuration management services.

COMPASS+ leverages more than 30 years of excellence in submarine engineering.

Using a combined set of commercial and customized components, COMPASS+ is a unique design and capability tool that integrates structures, electrical capability and safety features to analyse tangible design outcomes.

Designed to demonstrate the capability of a platform as delivered by the fitted and planned systems on the vessel, COMPASS+ takes into account fit opportunities and evolving threat characteristics. COMPASS+ allows users to rapidly assess the impact of design changes to function, architectural elements, and system addition/removal on overall submarine capability.

We provide comprehensive cost modelling and analysis services to help you in your next major procurement decision.

We have unrivalled understanding and knowledge to help you navigate and interpret the complexities of the transition from design and build contractor to end-user ownership.

We apply human factors engineering principles to the design and improvement of complex technical systems to optimise the human component of capability.

Integrating cutting edge organisational and behavioural insights to enhance performance, our innovative training consultancy supports the development of pro-active, professional, and highly skilled personnel within a regulated environment.

We support the safety of your resources, including setting safety requirements, identifying hazards, assessing risks, ensuring compliance, and providing assurance through the production of safety case artefacts.

We provide integrated logistics support across a range of engineering and technical domains to support pre and post-delivery for new or modified ships and submarines.