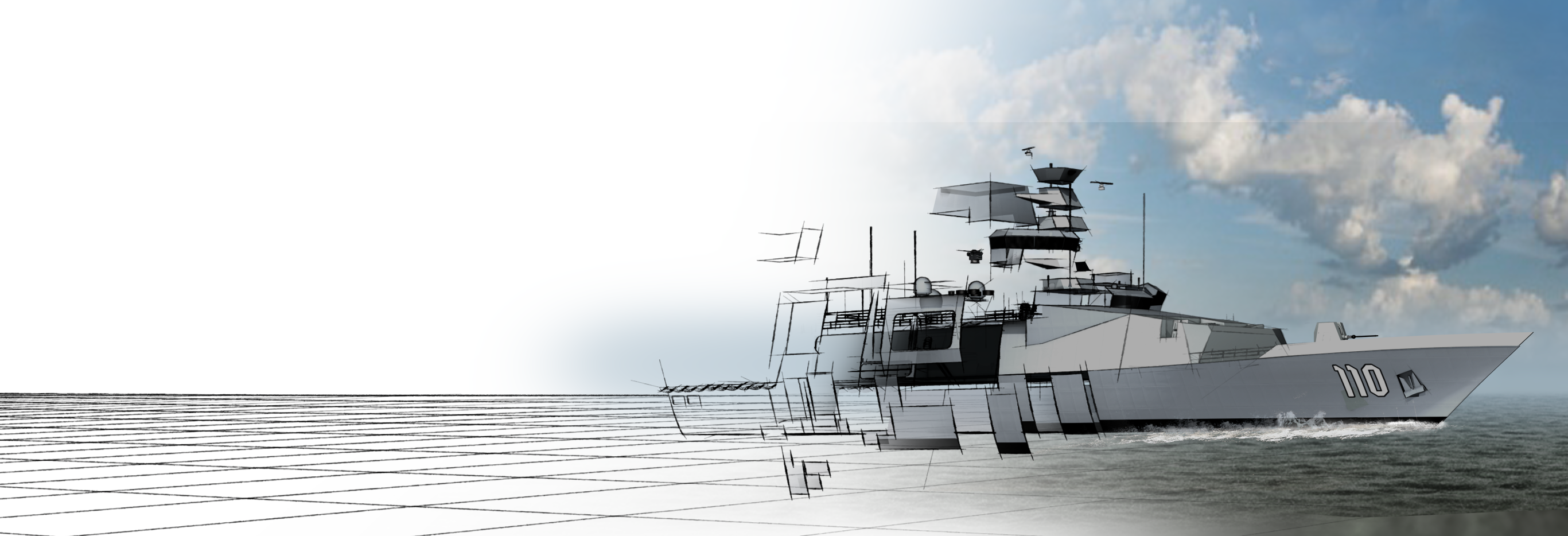

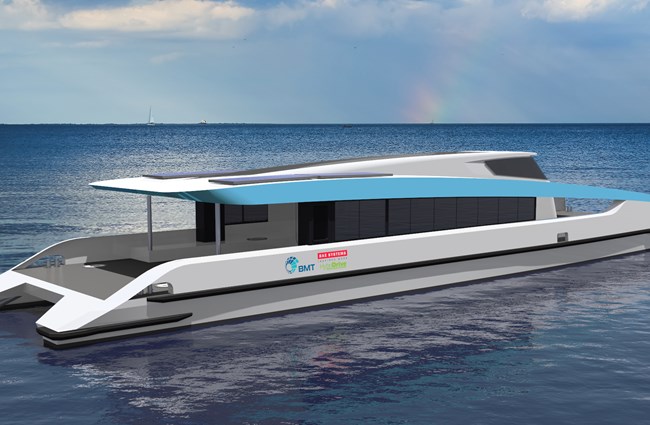

We develop exceptional vessel designs that meet the exacting speed, performance, range, seakeeping, and efficiency requirements of operators and shipyards around the world.

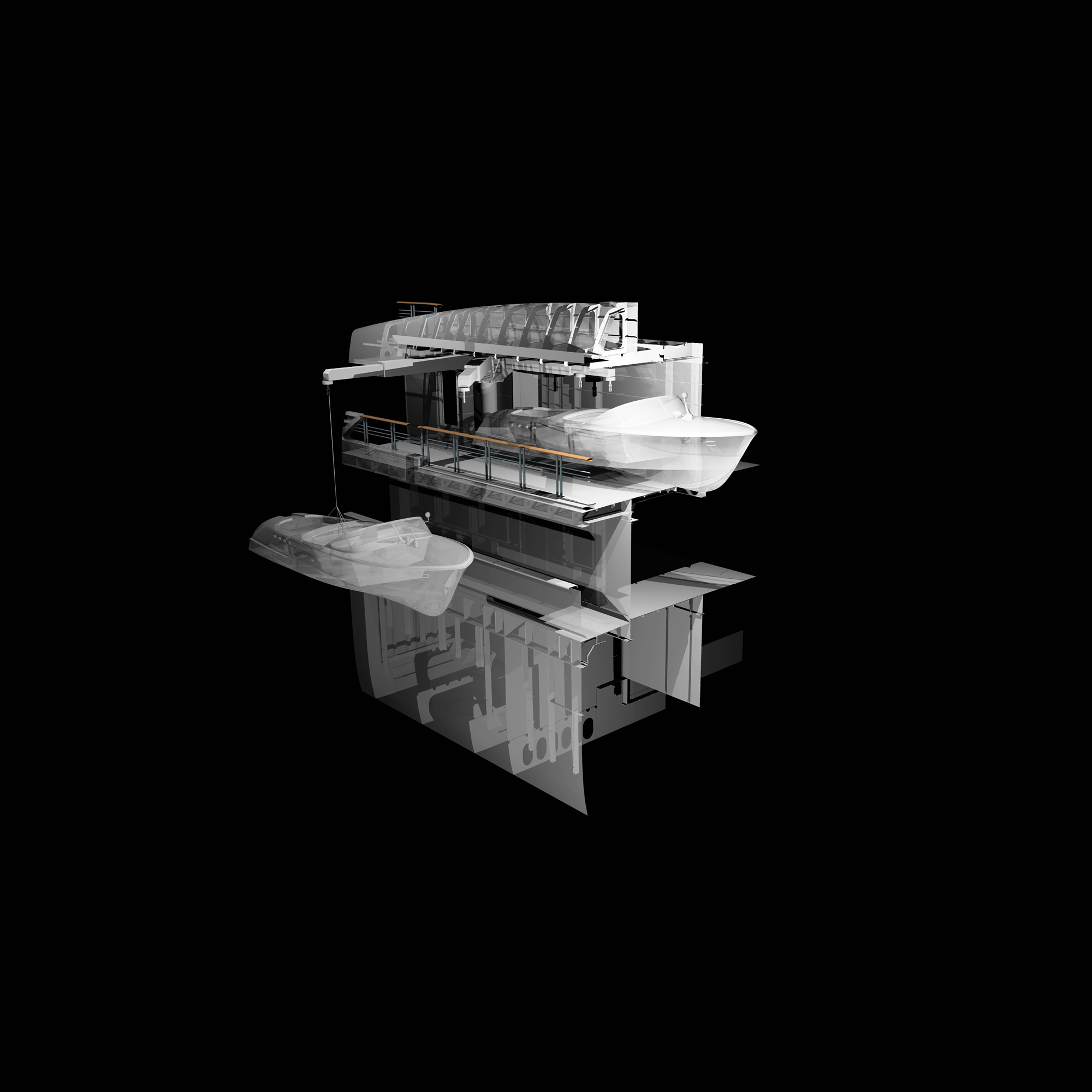

We work with you closely to develop concepts and preliminary designs that meet all of your functional requirements, and we bring to bear our decades of experience in the entire process of whole-vessel engineering, from concept to detailed production design. We add significant value in the early stages of design development and ensure that the final design is practical and feasible without compromising the original intent.

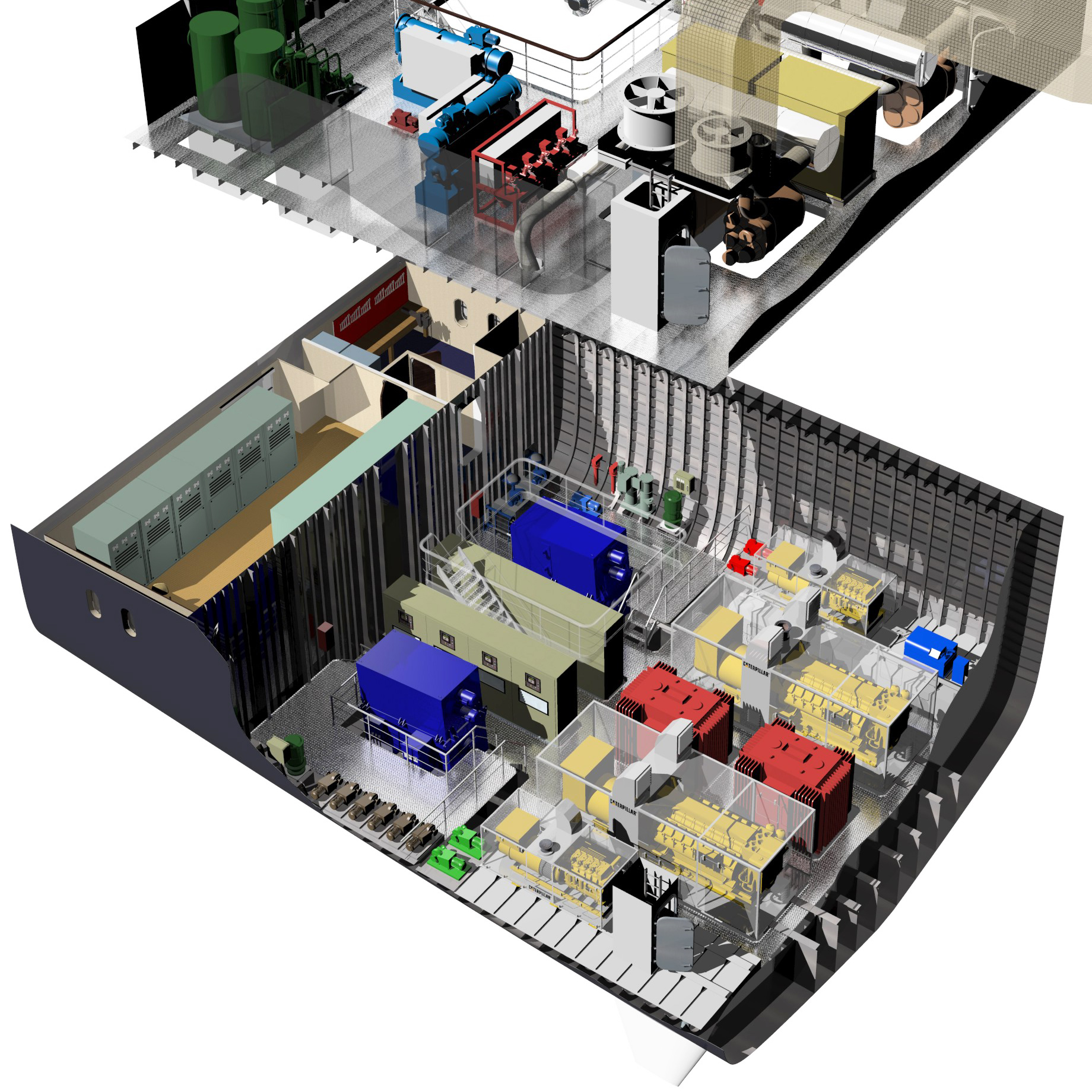

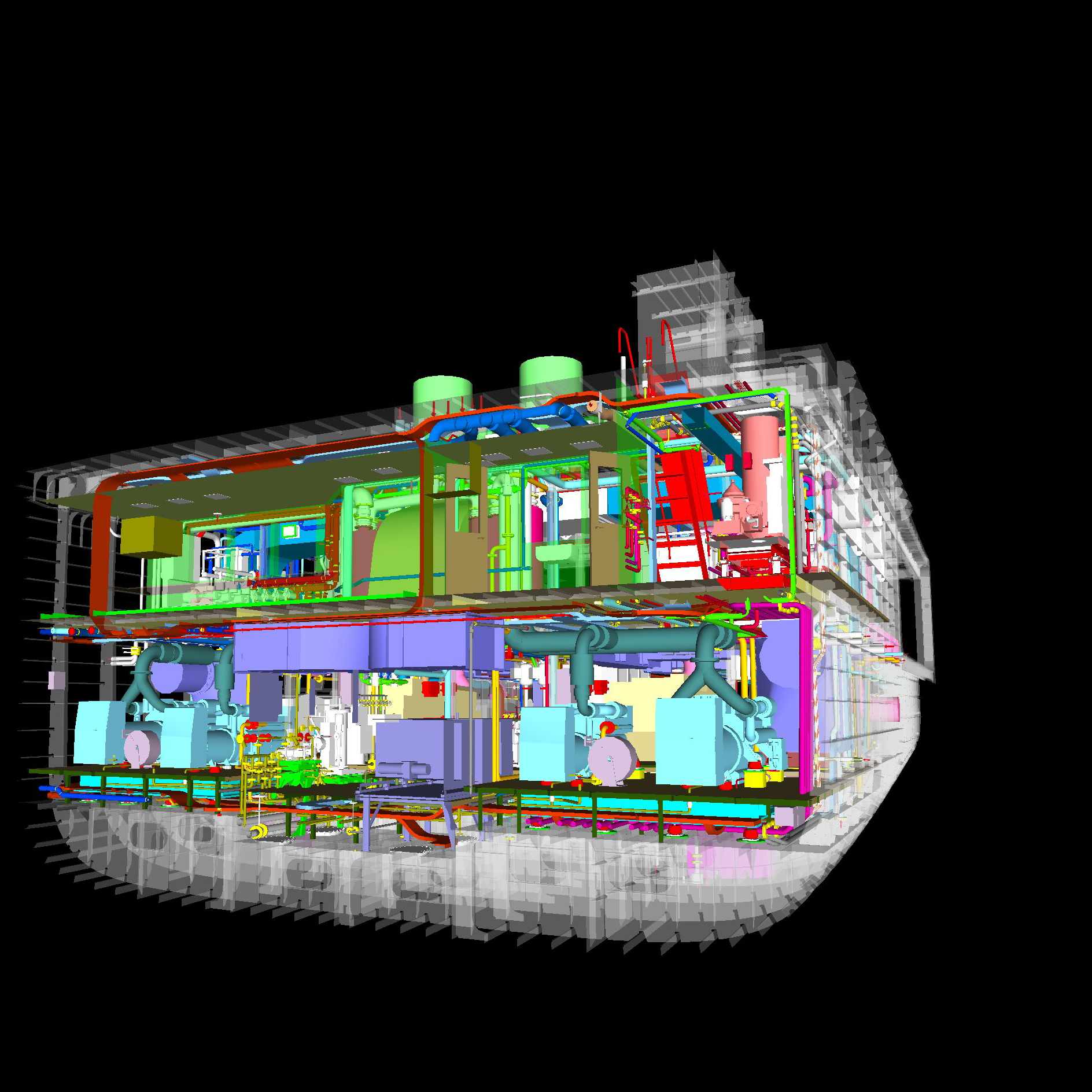

Thanks to our unrivalled knowledge of the design of steel, aluminium and composite structures and our unique proprietary software, we’ve helped create some of the world’s most advanced marine systems and can offer designs to meet even the most challenging requirements. Our team of expert mechanical engineers have the tools and experience to design the most appropriate and efficient machinery and systems to operate to exact specifications.

We can collaboratively share ideas and technology and foster innovation in concept designs based on new or novel technology, advanced engineering, or innovative naval architecture solutions.

Whatever your requirements for technical support at the preliminary design stage, we have the expertise to develop practical, feasible engineering solutions for a concept without compromising your original design requirements.

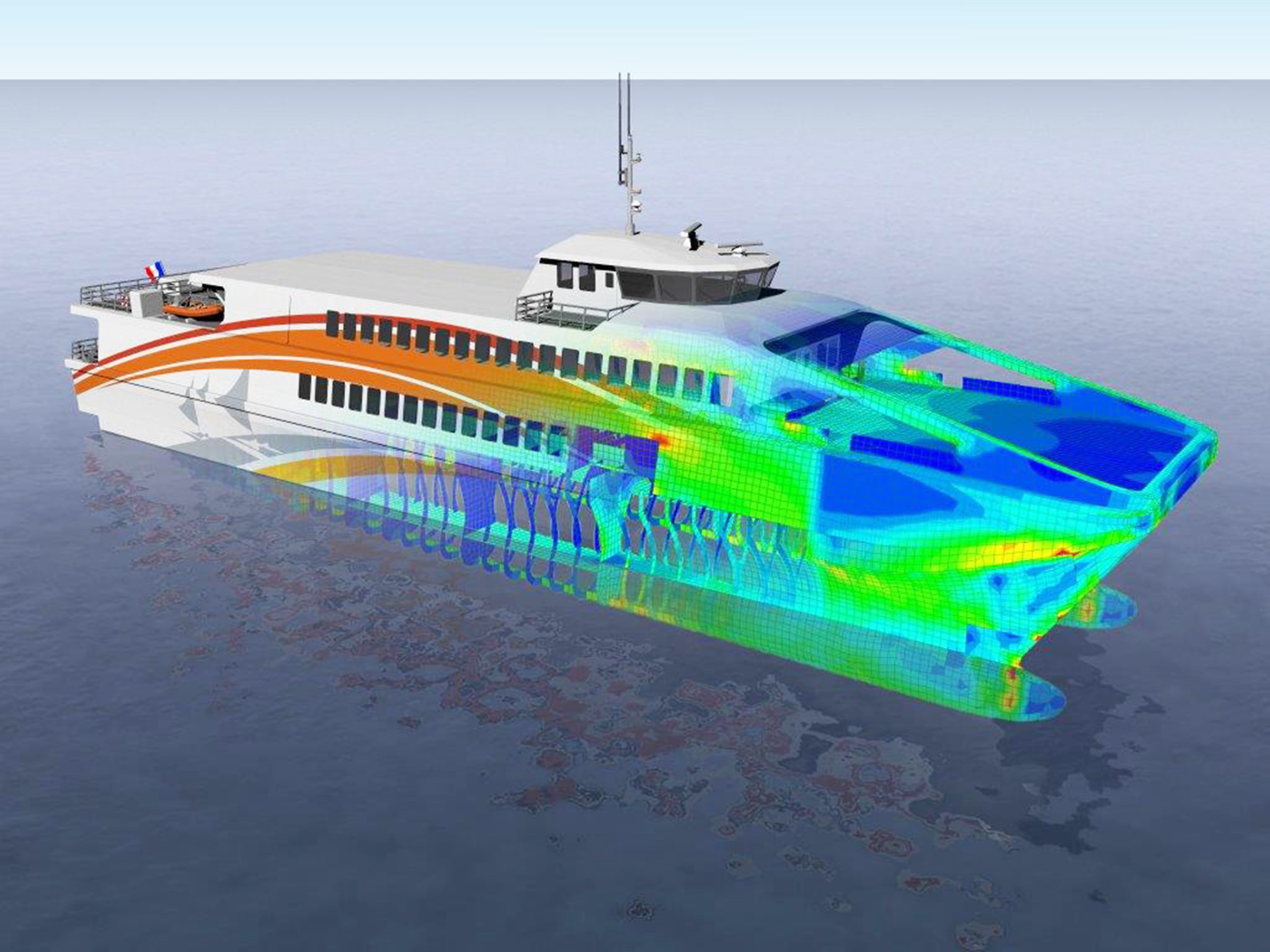

Our outstanding reputation in hull-form design and development is founded on vessels that offer excellent seakeeping ability, low resistance, and high propulsive efficiency. Additionally, our background in configuring conventional and high-tech propulsion systems, together with our experience in integrating active stabilising and dynamic positioning systems, means that we provide the highest levels of capability for even the most demanding owners.

Our front-end design services include:

● Hull-form design and development

● Hydrodynamic model testing

● Performance predictions

● Weight assessments and stability analysis

● Specification development

● Concept design development

● Propulsion, machinery, and systems layout

● Tender level designs and vessel specifications