Integrity monitoring and advisory

Our integrity management services help to determine whether assets are operating as designed, reducing potential downtime and minimizing risk.

Integrity monitoring and management are essential for determining whether your resources are operating as designed, reducing potential downtime and minimising risk.

Our customised monitoring systems are utilised worldwide on FPSOs, Semi-Submersibles, Spars, TLPs, SPM buoys and fixed platforms. They provide a complete understanding of an asset’s long-term integrity and operational decision-making by taking a more holistic approach to monitoring the environment and the structural response.

For those areas of the world experiencing seasonal weather extremes, our maintenance team can individually inspect and maintain integrity-monitoring systems in preparation, ensuring readiness. If necessary, repairs are made, damaged units are replaced, and outdated equipment is upgraded.

Operators have found that such preparations for hurricane, typhoon or cyclone season pay off when the environment and vessel response data acquired during hurricane evacuation feeds into and informs of the fixed or floating resource and mooring inspections required before restarting production.

BMT DEEP captures vast amounts of data from Internet of Things (IoT) devices and securely stores and processes the data in the Cloud allowing you to monitor an asset’s response to the environment in near real-time, remotely and safely.

We help you reduce risk and potential downtime by monitoring your assets constantly and effectively.

Platform performance and environmental conditions, such as wind speed, current profiles, air gap, and wave height, can be simultaneously monitored in real-time using our IMMS. Our systems are found on many floating offshore oil facilities and subsea risers, including tension leg platforms, spars, and subsea risers (steel catenary and free-standing).

We implement and maintain management systems compliant with internationally recognised standards covering quality, health and safety and environmental management. We are certified in ISO 9001, ISO 14001, and ISO 18001.

We are leaders in the aerodynamics and flight safety of offshore helicopter operations in the oil and gas industry. We help you to ensure that your helideck monitoring system provides onshore and offshore users with compliant data, customize displays and include additional features such as Motion Severity Index to suit your requirements.

We have a long history of supplying hull structural and motion monitoring systems and bring a unique combination of experience in providing permanent marine monitoring and advisory systems for offshore facilities.

Tendon Tension Monitoring Systems monitor tendon health and platform weight distribution in both Installation and Operation Mode. We provide two types of TTMS: porch-based systems and in-line systems.

Maintenance of the correct top tension ratio in vertical risers is essential for safe operations. We provide a system for directly monitoring tension in top-tensioned risers that is without parallel in the industry.

Bundled hybrid risers are multiple risers supported by a central core pipe offset from the FPSO. We offer a comprehensive system for monitoring the integrity of bundled hybrid risers.

The need for riser integrity monitoring has accelerated as operators strive to understand better structural issues and potential risks associated with riser systems in increasing water depths and hostile environments.

We provide monitoring systems for many types of risers and flowlines, including Buoyancy Supported Risers (BSRs), Steel Catenary Risers (SCRs), Steel Lazy Wave Riser (SLWR), Single Line Offset Risers (SLORs), Free-Standing Hybrid Risers (FSHRs), Multi-Bore Hybrid Risers (MHRs) and Oil-Offloading Lines (OOLs).

Our Anchor Leg/Load Mooring systems provide valuable information for safe operations, forensic engineering, and the validation of design codes for floating moored structures.

We can collect mooring line tension simultaneously with metocean parameters on a standard time base via an IMMS.

We deliver real-time operational and environmental data and critical control functions to lower risk and increase safety and active awareness during tanker hook-up and disconnect decisions for marine terminal and FPSO loading operations.

Our pipeline and materials engineering services team offer specialised engineering and expertise, research, consulting, and software to help you maximise pipeline efficiency while minimising risk.

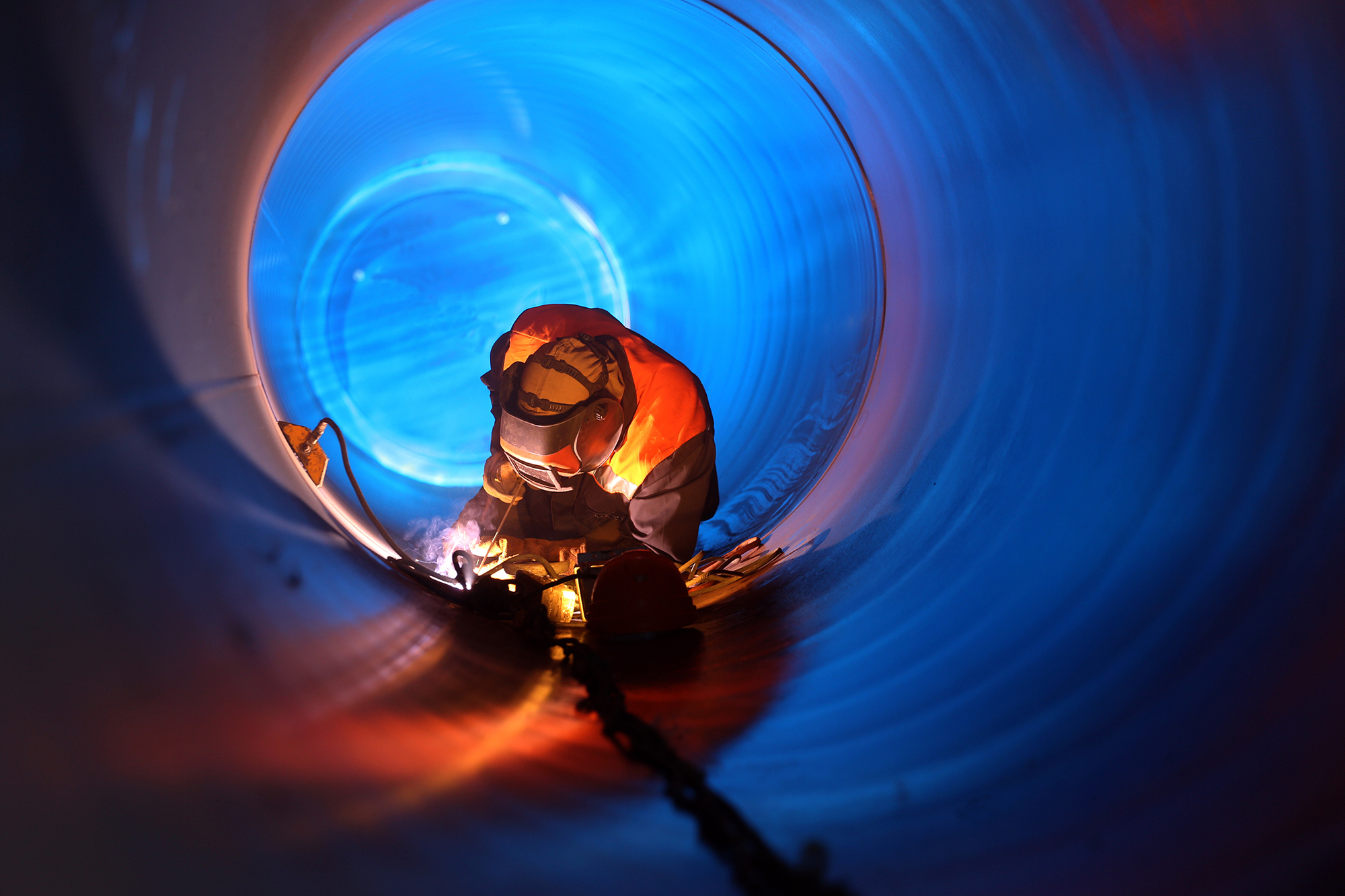

Our expertise in the areas of structures, materials, inspections, welding, and testing helps you understand and anticipate the root cause of pipeline fatigue and fracture and develop strategies to mitigate the potential for repeat failures.

Key services:

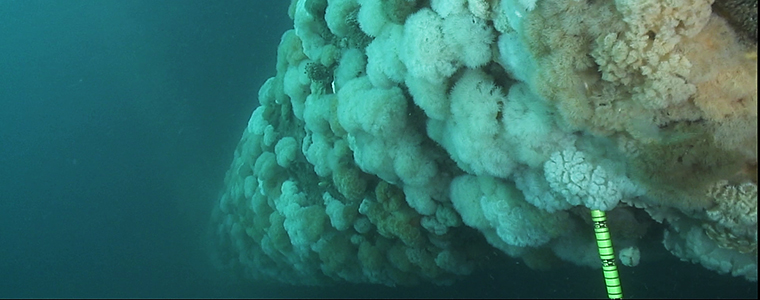

Offshore installations and pipelines can become colonised by marine organisms, impacting efficiency and safety.

Our understanding of the extent and form of colonisation helps you assess, prevent, and rectify problems resulting from fouling.

The Independent Remote Monitoring System (IRMS) allows operators to maintain remote communications with floating assets and receive critical environmental and performance data in real-time during an evacuation, independent of the assets power supply and communication system.

The system provides operators with critical environmental and dynamic performance data in real-time and video and still image capture of actual conditions offshore for effective decision making. Initially designed for monitoring abandoned platforms during severe weather conditions in the Gulf of Mexico to provide an early assessment of post-evacuation platform conditions for expedited re-boarding, the IRMS can be utilised to monitor any vessel, whether cold stacked or operational.

Our jack-up advisory system provides the operator with accurate information on sea conditions and motions when moving on and off, leading to less time waiting on weather, reduced exposure to the risk of incidents, and fewer commercial disputes between operators and contractors.

The system can provide real-time data on motion and sea state and advise whether a potential move on or off location is within operational limits. As a result, the jack-up platforms' owners and operators (onshore and offshore) make safer and efficient decisions during borderline weather conditions.