Dynamic modelling of materials

We lead welding engineering with a complete range of procedure development, material selection, simulation, testing, and forensic services and provide troubleshooting, production, and code compliance solutions.

We provide innovations in products and processes to help improve efficiency and enhance product safety and reliability for customers in the marine, offshore facility, pipeline, power generation, mining, civil structure, military and general manufacturing industries.

Our welding engineering and technology group is also ideally placed to answer questions about welding metallurgy, weld strength/toughness and practical welding procedures or techniques.

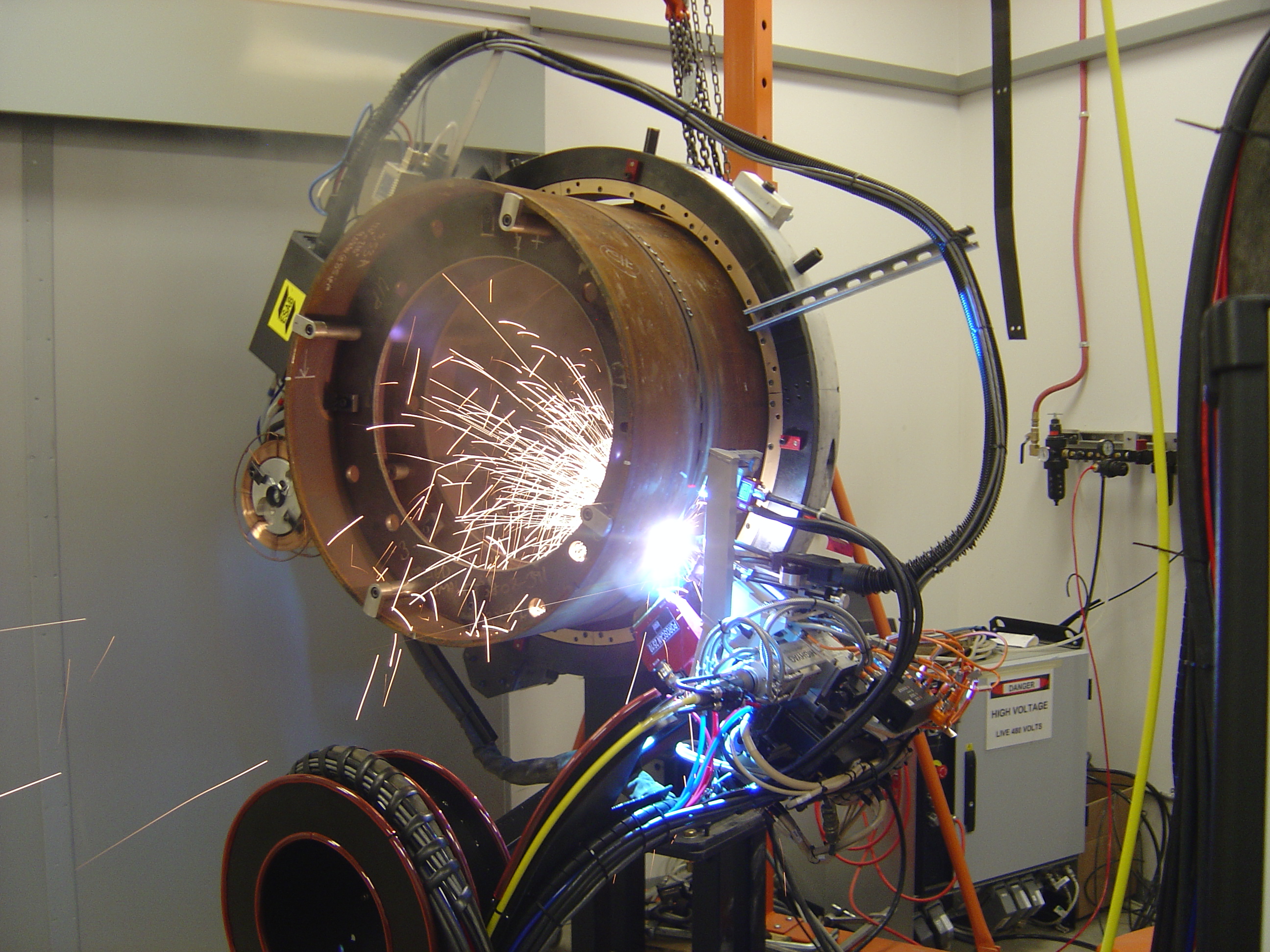

Our welding and fabrication facility can simulate different welding conditions to develop welding procedures, evaluate welding equipment or consumables and understand the implications of various parameters, conditions or equipment.

Research targeting the expansion of industry weld behaviour and the parameters that efficiently produce sound welds provides welding engineering support. We review the effects or potential for hydrogen cracking, lack of fusion, porosity, and laminations. Weld procedures, consumables, and technologies are evaluated, demonstrated, and advanced through physical trials and simulation. Production and in-service welding and repair solutions are developed according to industry standards, codes, and regulations.

Materials are evaluated to support design, maintenance, and forensic investigations. Metals, welding, and mechanical issues are considered to ensure compliance with codes and standards, enhance construction and repair solution success and reduce the potential for in-service degradation and failure.

We can support vintage and modern design and repair solution development, specification, and documentation. Stress analysis, material behaviour (strength, fatigue, and fracture), testing, and research are employed in root-cause failure analysis.

We operate machining, welding, mineral, component, and full-scale testing laboratories. Customized material and pipe tests and advanced finite element modelling are used to characterize buckling, fatigue, and fracture and identify failure's root cause.

We specialise in the mathematical modelling and simulation of engineering problems, which helps you safely and accurately assess operational issues before implementation.

We evaluate the suitability or interaction of materials to support design, maintenance, and investigations.

Our cost-effective, high-quality services help us consistently meet exacting standards in the volatile oil and gas industry.

We apply engineering technical expertise to various asset integrity assurance and management programs, assisting you in meeting and exceeding industry standards, codes, and regulations.