Automation and robotics for mined materials handling

Handling mined materials in bulk involves high volumes and numerous hazards. Combined with the need to maximise productivity, there is a strong case for using automation and robotics.

We are at the forefront of machinery developments and offer bespoke, intelligent solutions that allow you to benefit from new AI and robotics technologies.

Advanced modelling and simulation techniques are at the heart of our intelligent design support, automation, and remote operation. These machines help you handle materials more efficiently and be more productive by meeting your specific requirements.

We take pride in delivering leading-edge technology solutions to suit the unique requirements of each of your sites.

Our products are built on our highly customisable ROAR (Remote Operations, Automation and Robotics) software platform developed in-house to allow us to very rapidly customise our solution to meet your requirements. If you need a technology solution that is not available off the shelf, we are here to help.

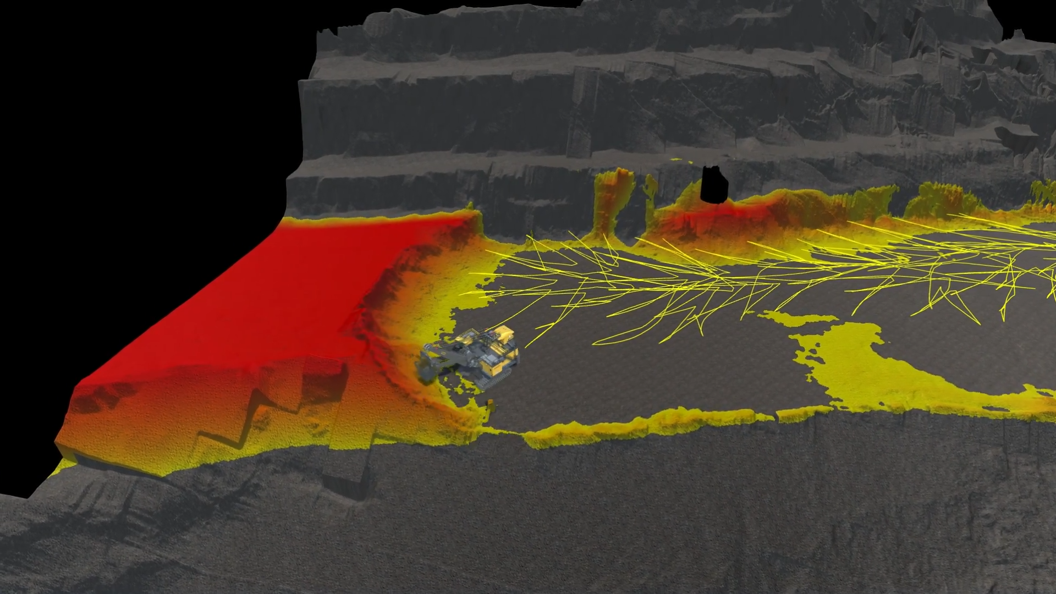

Our advanced modelling techniques enable digital monitoring and imaging of mining environments.

By sensing position, orientation, and environment, users can construct an accurate image of the environment to view and interrogate. All components, including machinery, can be accurately represented within the environment to model how they interact, either for remote operation or automation.

Our sophisticated 3D modelling techniques create the perfect test ground for automated mining machinery. Our virtual environment enables machinery models to be engineered and measured under all conditions, giving you greater insight into guidance, control, collision avoidance and monitoring.

From dragline terrain scanning to remote and autonomous operation, our modelling, automation and robotics experts help make mining operations more efficient while keeping people safe.

We give you the capability to remotely view and operate your facilities across the entire value chain, from “Pit to Port”. Our innovative solutions are currently being used on Mobile Mining Equipment, Yard Machines, Rail Transport and Ports to give our customers a consistent and enhanced view of their operations.

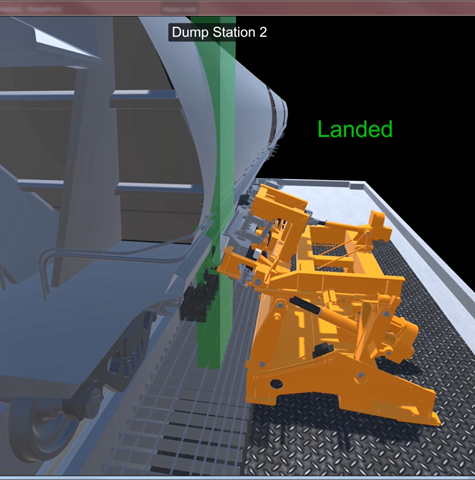

We help you overcome the costly problems caused by ‘sticky’ coal being discharged from rail wagons at port terminals.

Previously, the only way to clear blockages was to manually dislodge the coal, leading to lengthy, costly delays and safety issues. Our automated Wagon Vibrator overcomes these problems by detecting blockages, engaging the wagon and delivering a high-frequency oscillation to dislodge the coal.

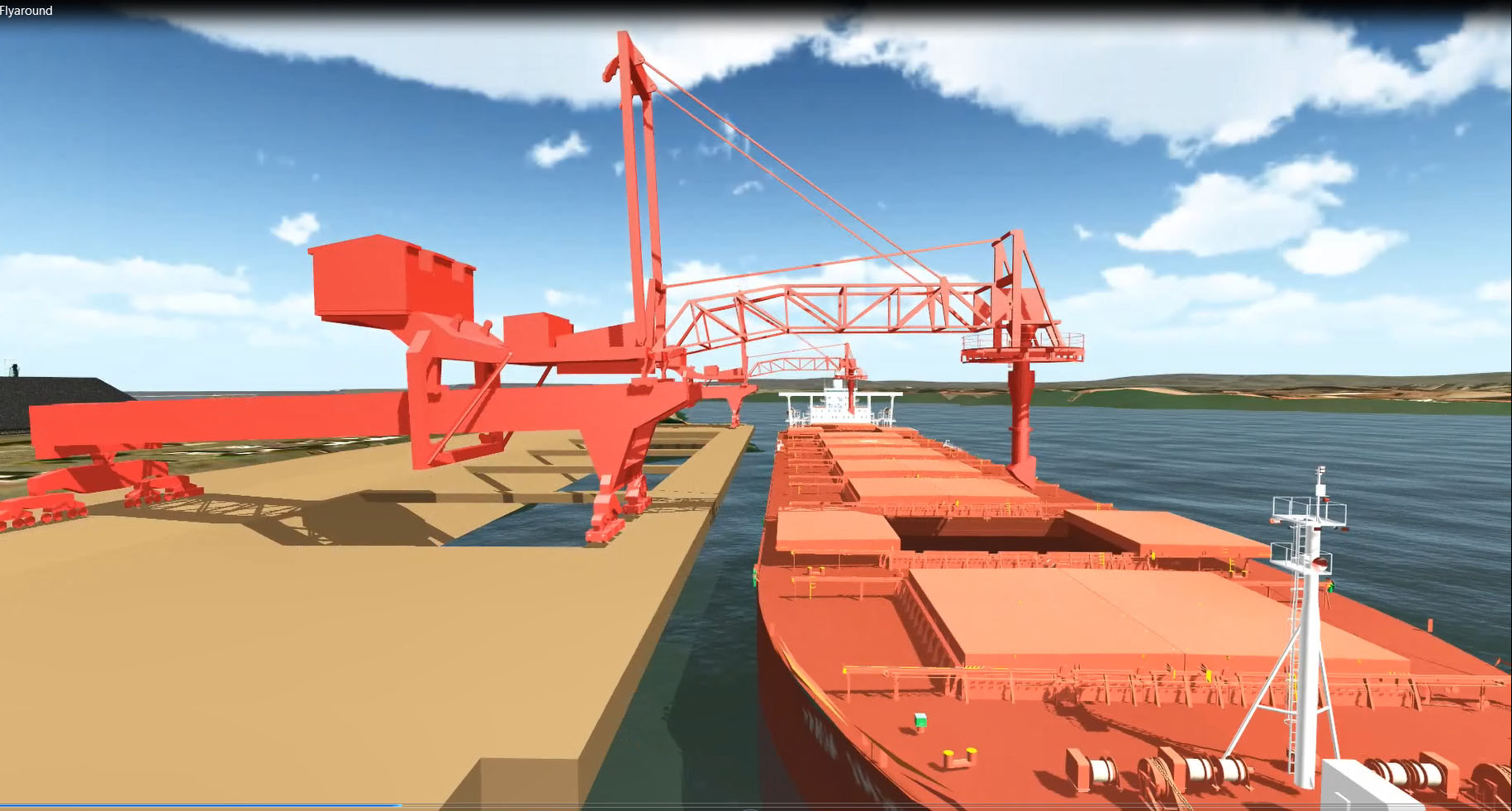

Self-unloading vessels are vital in transferring large loads of mined materials safely, rapidly, and efficiently. Our experts can design the entire system, including mechanical, structural, electrical and control details for conveyors, bucket wheel reclaimers, gantries, booms, ventilation, and dust control systems.

Quickly and safely transferring loads from trains to vessels is a challenge. Still, our technical skills and extensive experience will help you design automated systems that ensure consistent, continuous load-out of trains. We can help you improve your operating efficiencies, achieve your required load-in and load-out rates, maximise stockpile capacity, minimise the use of the mobile plant, and reduce the cost-per-tonne handling rate.

Assessing the integrity and operation of your asset is easier with BMT DEEP.

We have built a reputation for excellence by designing advanced, innovative mining machinery that helps extract commodities more efficiently while increasing safety and environmental protection.

We have a global reputation for designing bulk materials handling systems that transfer commodities such as coal and iron ore quickly and safely, day in and day out.